Decarbonizing Thermal Power with Hydrogen Co-Firing: Transitioning Coal and Gas to Cleaner Futures

The global thermal power sector stands at a critical transition point where hydrogen co-firing emerges as the most viable pathway for decarbonizing existing fossil fuel infrastructure while maintaining grid reliability and economic viability. This transformative approach enables coal and natural gas power plants to reduce carbon emissions significantly while preserving essential baseload and peaking capacity during the renewable energy transition. Hydrogen co-firing thermal power represents a strategic bridge technology that maximizes existing infrastructure value while creating pathways toward complete decarbonization as hydrogen supply scales and technology matures.

Technical Foundations of Hydrogen Co-Firing

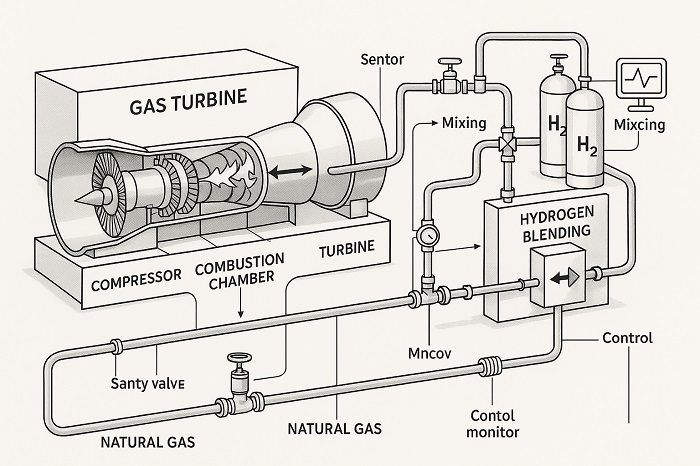

Hydrogen co-firing thermal power systems modify existing combustion processes to accommodate hydrogen-natural gas blends or hydrogen-coal mixtures that reduce carbon emissions while maintaining operational reliability and performance characteristics. The fundamental chemistry of hydrogen combustion produces only water vapor and heat, enabling substantial emission reductions proportional to the hydrogen content in fuel blends.

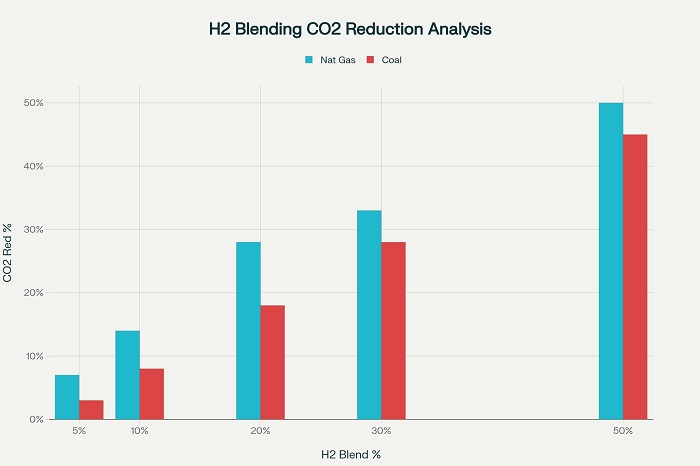

Natural gas turbines demonstrate exceptional compatibility with hydrogen co-firing, capable of achieving blend ratios ranging from 5% to 50% hydrogen by volume without major equipment modifications. Advanced combustion systems can accommodate even higher hydrogen percentages, with some installations targeting 100% hydrogen capability through dedicated upgrades and fuel system modifications.

The combustion characteristics of hydrogen differ significantly from natural gas, featuring higher flame speeds, wider flammability limits, and different adiabatic flame temperatures that require careful consideration during system design and operation. These differences necessitate modifications to burner systems, fuel injection equipment, and combustion control systems that maintain stable operation across varying hydrogen concentrations.

Hydrogen’s lower energy density compared to natural gas means that higher volumetric flow rates are required to maintain equivalent power output, necessitating upgrades to fuel supply systems, piping, and flow measurement equipment. Additionally, hydrogen’s tendency to cause embrittlement in certain metal alloys requires material compatibility assessments and potential component replacements to ensure long-term reliability.

Coal power plants present greater technical challenges for hydrogen co-firing due to their fundamentally different combustion processes and fuel handling systems. However, hydrogen can be introduced through various pathways including direct injection into furnaces, gasification-based systems that produce hydrogen from coal, or hybrid approaches that combine separate hydrogen and coal combustion systems.

The thermal characteristics of hydrogen combustion enable improved heat transfer and combustion efficiency in many applications, potentially offsetting some of the energy density disadvantages while providing operational benefits including faster startup times, improved turndown capabilities, and enhanced grid services performance.

Global Implementation and Demonstration Programs

Leading thermal power operators worldwide have initiated comprehensive hydrogen co-firing programs that validate technical feasibility while establishing operational procedures and economic frameworks for broader deployment. These demonstration projects provide critical real-world data that guides industry-wide adoption while building stakeholder confidence in hydrogen technologies.

Georgia Power’s Plant McDonough-Atkinson represents the most advanced hydrogen co-firing demonstration globally, successfully completing tests blending up to 50% hydrogen with natural gas in an advanced class gas turbine. This landmark achievement, completed in collaboration with Mitsubishi Power, demonstrated approximately 22% reduction in CO2 emissions while maintaining full operational capability across multiple load conditions.

The testing program systematically evaluated hydrogen blends ranging from 5% to 50%, conducting comprehensive performance assessments across several weeks of operation. The turbine conversion from steam-cooled to air-cooled configuration, incorporating J-series combustion technology with proven hydrogen capability, enabled the successful demonstration while providing operational benefits including faster startup times and reduced maintenance requirements.

European hydrogen co-firing initiatives focus on transitioning coal-fired power plants to cleaner alternatives through multi-stage conversion programs. Germany’s Altbach-Deizisau and Heilbronn plants represent comprehensive transitions from coal to natural gas as intermediate steps toward 100% hydrogen operation by the 2030s, demonstrating systematic approaches to fossil fuel plant decarbonization.

The GE Vernova-led consortium supporting EnBW’s plant conversions incorporates hydrogen-ready designs that accommodate future fuel transitions while maximizing near-term emission reductions through natural gas conversion. These projects demonstrate how thermal power infrastructure can be progressively decarbonized through staged implementation programs that maintain grid reliability while achieving environmental objectives.

Austria’s Donaustadt power station demonstrates hydrogen co-firing in heavy-duty gas turbines under commercial operation conditions, testing 15% hydrogen blends that achieve 33,000 tonnes of annual CO2 emission reductions. This €10 million upgrade provides valuable operational experience for similar conversions while demonstrating hydrogen co-firing’s compatibility with existing grid obligations.

India’s pioneering green hydrogen blending operation at NTPC Kawas represents the first successful integration of renewable-produced hydrogen with natural gas distribution systems, achieving 5% blending with regulatory approval for scaling to 20% concentrations. This project demonstrates integrated approaches that combine renewable electricity, electrolysis, and thermal power applications within unified energy systems.

Advanced Gas Turbine Hydrogen Integration

Modern gas turbine technology demonstrates remarkable adaptability to hydrogen co-firing applications, with manufacturers developing specialized combustion systems specifically designed for high hydrogen content operation. These advanced systems enable utilities to achieve substantial emission reductions while maintaining operational flexibility essential for grid stability and renewable energy integration.

Mitsubishi Power’s J-series gas turbines lead hydrogen co-firing development with proven capabilities for blending ratios exceeding 50% hydrogen while maintaining operational performance and reliability standards. The company’s hydrogen combustion technology incorporates specialized burner designs, fuel injection systems, and combustion control algorithms optimized for hydrogen’s unique characteristics.

GE Vernova’s hydrogen-ready turbine designs accommodate fuel transitions from natural gas to hydrogen blends and eventually pure hydrogen through modular upgrade approaches that minimize downtime and capital requirements. These systems incorporate advanced combustion technologies, materials selections, and control systems specifically engineered for hydrogen applications.

Siemens Energy’s gas turbine portfolio increasingly emphasizes hydrogen capability, with multiple installations demonstrating successful hydrogen co-firing operations across different turbine classes and applications. The company’s approach focuses on comprehensive system integration that addresses fuel supply, combustion, and power conversion aspects of hydrogen operation.

The technical challenges of hydrogen co-firing include managing NOx emissions that can increase at certain operating conditions, addressing hydrogen’s propensity for flashback and auto-ignition, and accommodating hydrogen’s different thermal and flow characteristics compared to natural gas. Advanced combustion systems employ sophisticated control algorithms, specialized burner designs, and enhanced safety systems that address these challenges while maintaining reliable operation.

Fuel supply systems for hydrogen co-firing require careful design to accommodate hydrogen’s low density, high diffusivity, and safety considerations including leak detection and prevention systems. Advanced installations employ dedicated hydrogen supply infrastructure, specialized compression and storage systems, and comprehensive safety protocols that ensure reliable operation while minimizing risks.

Coal Plant Transition Strategies

Coal-fired power plants require more complex approaches to hydrogen integration due to fundamental differences in combustion processes, fuel handling, and plant design compared to gas turbines. However, multiple pathways enable coal plants to incorporate hydrogen while transitioning toward cleaner operation and eventual fuel conversion.

Direct hydrogen injection into coal furnaces represents the most straightforward approach, utilizing existing combustion chambers while adding hydrogen supply and injection systems. This method can achieve meaningful emission reductions while requiring minimal plant modifications, though hydrogen percentages remain limited by furnace design constraints and operational considerations.

Coal gasification integrated with hydrogen production creates opportunities for comprehensive plant conversions that maintain existing steam cycles while replacing coal combustion with hydrogen-fired systems. These approaches can achieve substantial emission reductions while preserving plant infrastructure investments and maintaining employment in coal-dependent regions.

Hybrid combustion systems combine separate coal and hydrogen firing systems that can operate independently or in coordination depending on fuel availability, grid requirements, and economic conditions. This flexibility enables operators to optimize fuel selection based on market conditions while maintaining operational capability across varying scenarios.

India’s coal-to-hydrogen roadmap demonstrates systematic approaches for transitioning coal infrastructure toward hydrogen production and utilization, targeting demonstration plants that validate technical and economic feasibility while establishing supply chains and operational procedures. This comprehensive program addresses gasification technologies, carbon capture and storage integration, and hydrogen utilization across multiple applications.

The integration of carbon capture, utilization, and storage systems with hydrogen co-firing enables coal plants to achieve even greater emission reductions while creating valuable byproducts from captured CO2. These integrated approaches demonstrate how existing coal infrastructure can contribute to circular economy principles while transitioning toward cleaner operation.

Economic Drivers and Market Mechanisms

The economics of hydrogen co-firing thermal power depend critically on hydrogen supply costs, carbon pricing mechanisms, and operational flexibility values that vary significantly across markets and regulatory environments. Current hydrogen costs limit widespread deployment, but declining production costs and increasing carbon prices create improving economic conditions for hydrogen co-firing applications.

Natural gas price volatility increasingly favors hydrogen co-firing as a hedging strategy that reduces fuel cost exposure while providing emission benefits and regulatory compliance advantages. Utilities can optimize fuel selection based on relative prices while maintaining operational flexibility and environmental performance.

Carbon pricing mechanisms provide direct economic incentives for hydrogen co-firing through reduced emission costs that improve operational economics proportional to hydrogen content in fuel blends. European carbon prices exceeding €80 per tonne create substantial value for emission reductions achievable through hydrogen co-firing.

Grid services markets increasingly value the operational flexibility provided by hydrogen co-firing systems, which can rapidly adjust output, provide frequency regulation, and support renewable energy integration through flexible operation. These ancillary service revenues help offset hydrogen fuel costs while providing system benefits.

Government incentive programs specifically targeting hydrogen co-firing provide financial support that bridges the gap between current costs and commercial viability. Production tax credits, investment incentives, and research funding accelerate deployment while building industry experience and supply chains.

The stranded asset risk for coal and gas plants without decarbonization pathways creates strong economic incentives for hydrogen co-firing investments that preserve asset value while meeting environmental requirements. Hydrogen co-firing enables plant life extensions and continued operation under increasingly stringent emission regulations.

Environmental Impact and Emission Reduction

Hydrogen co-firing thermal power achieves substantial environmental benefits through direct emission reductions, improved air quality, and reduced lifecycle environmental impacts compared to conventional fossil fuel combustion. The magnitude of benefits scales proportionally with hydrogen content while providing immediate improvements that complement longer-term decarbonization strategies.

Carbon dioxide emission reductions from hydrogen co-firing range from 7% for 20% hydrogen blends to over 22% for 50% hydrogen content, providing immediate climate benefits while maintaining grid reliability and operational flexibility. These emission reductions contribute directly to utility and national climate targets while demonstrating measurable progress toward decarbonization objectives.

Local air quality improvements from hydrogen co-firing include reductions in particulate matter, sulfur compounds, and other pollutants associated with fossil fuel combustion. These benefits particularly advantage urban and industrial areas where thermal power plants contribute to air quality concerns.

Water consumption reductions in some hydrogen co-firing applications result from improved thermal efficiency and reduced cooling requirements, providing environmental benefits in water-stressed regions where thermal power plants compete for water resources with other users.

The lifecycle environmental impact of hydrogen co-firing depends critically on hydrogen production methods, with renewable-produced hydrogen providing the greatest environmental benefits while hydrogen from fossil sources with carbon capture offering intermediate improvements. Comprehensive lifecycle assessments guide optimization of hydrogen supply chains to maximize environmental benefits.

Noise reduction benefits from hydrogen combustion, which operates more quietly than conventional fossil fuel systems, provide additional environmental advantages particularly relevant for plants in urban or residential areas where noise regulations may limit operation.

Regulatory Framework and Safety Standards

Hydrogen co-firing thermal power operates within evolving regulatory frameworks that address safety, environmental, and grid reliability requirements while accommodating the unique characteristics of hydrogen as a power generation fuel. These frameworks continue developing as operational experience accumulates and technology demonstrates commercial viability.

Safety regulations for hydrogen co-firing address hydrogen’s flammability characteristics, storage requirements, and handling procedures that differ from conventional natural gas or coal systems. Comprehensive safety protocols cover hydrogen production, transportation, storage, and combustion aspects while ensuring worker safety and public protection.

Environmental regulations increasingly recognize hydrogen co-firing as an acceptable emission reduction technology, with some jurisdictions providing specific frameworks for hydrogen utilization in existing thermal power plants. These regulations balance emission reduction objectives with grid reliability requirements and economic considerations.

Grid reliability standards must accommodate hydrogen co-firing systems while ensuring continued ability to provide essential grid services including frequency regulation, voltage support, and emergency response capabilities. Regulatory frameworks evolve to recognize hydrogen systems’ unique operational characteristics while maintaining system reliability requirements.

International standards development for hydrogen co-firing addresses equipment specifications, operational procedures, and performance requirements that enable consistent implementation across different markets and jurisdictions. Organizations including ISO, IEC, and national standards bodies develop comprehensive frameworks for hydrogen power applications.

Professional certification and training requirements for hydrogen co-firing operations ensure adequate workforce capabilities while maintaining safety standards and operational reliability. These programs address hydrogen-specific technical knowledge, safety procedures, and emergency response capabilities essential for safe operation.

Future Development and Market Evolution

Hydrogen co-firing thermal power represents a transitional technology that enables immediate emission reductions while building toward eventual complete decarbonization as hydrogen supply scales and costs decline. The trajectory toward 100% hydrogen operation depends on continued technology development, infrastructure investments, and supportive policy frameworks.

Next-generation combustion technologies promise higher hydrogen blending ratios and improved operational performance through advanced materials, optimized combustion systems, and enhanced control algorithms. These developments enable greater emission reductions while maintaining operational reliability and economic competitiveness.

Hydrogen supply chain development, including production, storage, and transportation infrastructure, determines the scale and economics of hydrogen co-firing deployment. Coordinated infrastructure investments create economies of scale that improve hydrogen availability while reducing costs for thermal power applications.

Integration with renewable energy systems enables hydrogen co-firing thermal power plants to serve as both emission reduction technologies and grid balancing resources that support renewable energy integration. This dual functionality positions hydrogen co-firing as essential infrastructure for high-renewable energy systems.

International technology transfer and standardization accelerate global deployment while ensuring consistent safety and performance standards across different markets. Leading countries and companies develop expertise and technologies that can be adapted and deployed internationally, accelerating global decarbonization efforts.

The ultimate transition to 100% hydrogen operation requires continued hydrogen cost reductions, infrastructure development, and operational experience that demonstrates long-term viability. Hydrogen co-firing provides the operational experience and infrastructure foundation necessary for this eventual transition while delivering immediate environmental and economic benefits.