Hydrogen Fuel Cells in Power Plants: The Next Frontier in Electricity Generation

The global power generation landscape stands at the precipice of a revolutionary transformation. Hydrogen fuel cell power plants are emerging as the cornerstone technology that promises to redefine how we produce electricity, offering a clean, efficient, and scalable alternative to traditional fossil fuel-based generation. This technological shift represents more than an incremental improvement—it embodies a fundamental reimagining of stationary power generation.

The Evolution of Stationary Fuel Cell Technology

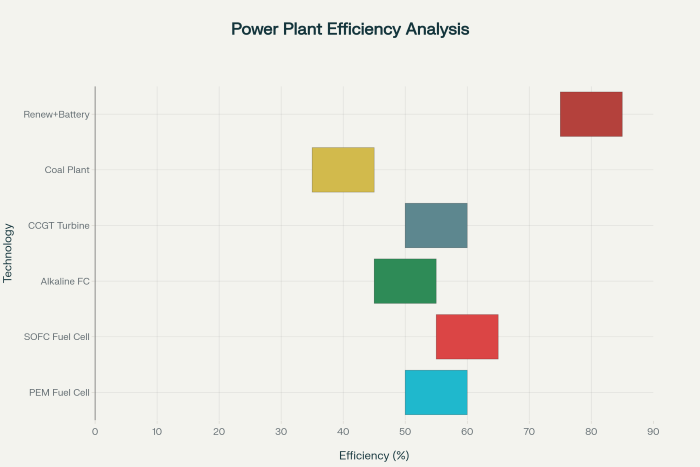

Stationary fuel cell systems have evolved dramatically from experimental installations to commercial-scale power plants capable of generating hundreds of megawatts. These electrochemical devices convert hydrogen directly into electricity without combustion, achieving remarkable efficiency rates that often surpass 60 percent in electricity generation and can reach over 85 percent when configured for combined heat and power applications.

The sophistication of modern hydrogen fuel cell power plants lies in their ability to provide consistent baseload power while maintaining the flexibility to respond rapidly to grid demands. Unlike traditional thermal power plants that require extensive startup procedures, fuel cell systems can reach full operational capacity within minutes, making them invaluable for grid stability and load balancing.

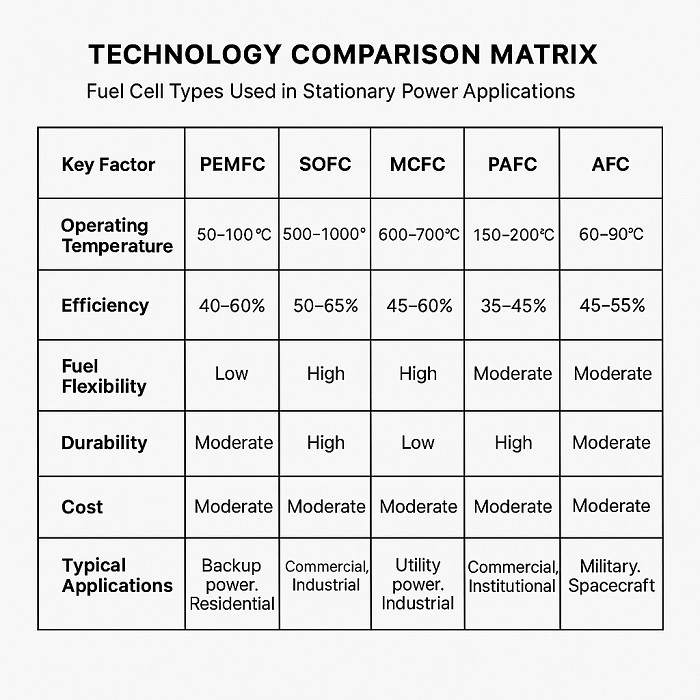

Contemporary installations demonstrate three primary fuel cell technologies dominating the stationary power market. Proton Exchange Membrane Fuel Cells operate at relatively low temperatures between 50-100°C, making them ideal for applications requiring quick response times and frequent cycling. Their ability to achieve rapid startup and shutdown cycles positions them perfectly for grid balancing and backup power applications.

Solid Oxide Fuel Cells represent the high-temperature solution, operating between 700-1000°C. This elevated operating temperature enables them to achieve superior electrical efficiency while generating high-grade waste heat suitable for additional power generation through steam turbines or industrial process applications. Their fuel flexibility allows operation on various hydrogen sources, including reformed natural gas during the transition period.

Alkaline Fuel Cells, while less common in large-scale applications, offer specific advantages in certain operational environments. Their tolerance to impurities and relatively simple construction make them suitable for specialized industrial applications where hydrogen purity might be challenging to maintain consistently.

Case Study Showcase: Leading Global Implementations

South Korea’s Ambitious Scale-Up

South Korea has positioned itself as the global leader in large-scale hydrogen fuel cell power plants deployment. The Shinincheon Bitdream facility stands as a testament to the commercial viability of fuel cell technology, generating 78.96 MW of electricity while simultaneously providing district heating services to surrounding communities. This combined approach maximizes the utilization of waste heat, pushing overall system efficiency beyond conventional power generation methods.

The recently announced 107.9 MW facility, scheduled for construction beginning March 2025 with an investment exceeding $550 million, represents the world’s largest hydrogen fuel cell power plant project. This installation will initially utilize hydrogen produced from natural gas reforming while preparing infrastructure for future green hydrogen integration as production costs decline and availability increases.

South Korean developers have demonstrated remarkable expertise in scaling fuel cell installations efficiently. The modular approach employed allows for phased construction and commissioning, reducing initial capital requirements while enabling rapid capacity expansion as demand grows. This methodology has proven particularly effective in urban environments where space constraints and environmental regulations favor clean generation technologies.

Japan’s Innovation Leadership

Japan’s approach to hydrogen fuel cell power plants emphasizes technological innovation and integration with existing energy infrastructure. The country’s commitment to hydrogen as a cornerstone of energy security has driven significant investments in fuel cell research and deployment across multiple scales.

Honda’s recent demonstration project in Shunan City exemplifies Japan’s focus on circular economy principles within the hydrogen sector. The facility utilizes by-product hydrogen from Tokuyama Corporation’s salt water electrolysis operations while incorporating repurposed automotive fuel cells, demonstrating the potential for creating integrated hydrogen ecosystems that maximize resource utilization.

Japanese installations consistently emphasize combined heat and power configurations, recognizing the substantial efficiency gains achievable through waste heat recovery. This approach proves particularly valuable in industrial zones where process heat demands align with electricity generation requirements, creating synergistic benefits that improve overall project economics.

The country’s regulatory framework has evolved to support distributed generation through fuel cells, enabling smaller-scale installations to contribute to grid stability while providing local communities with resilient power supplies. This distributed approach reduces transmission losses and enhances overall system reliability.

European Leadership in Clean Integration

European hydrogen fuel cell power plants focus heavily on renewable integration and carbon reduction objectives. The continent’s aggressive decarbonization targets have driven innovative approaches to incorporating fuel cells within broader renewable energy systems.

Germany’s Hyflexpower project successfully demonstrated 100 percent renewable hydrogen utilization in a 12 MW gas turbine, establishing proof of concept for larger-scale implementations. This achievement represents a crucial milestone in transitioning from natural gas-based operations to pure hydrogen systems.

The Netherlands has emerged as a testing ground for advanced fuel cell configurations, with several pilot projects exploring the integration of electrolysis and fuel cell systems to create energy storage and generation hubs. These installations demonstrate the potential for hydrogen fuel cell power plants to serve dual functions as both electricity generators and grid-scale energy storage systems.

Nordic countries have leveraged their abundant renewable energy resources to create green hydrogen production facilities coupled with fuel cell power plants. This integrated approach addresses seasonal energy storage challenges while providing dispatchable clean electricity during periods of low renewable output.

Technical Architecture and Performance Characteristics

Modern hydrogen fuel cell power plants incorporate sophisticated balance-of-plant systems that optimize performance across varying operational conditions. Advanced control systems continuously monitor stack temperatures, pressure levels, and reactant flows to maintain optimal efficiency while maximizing stack lifetime.

The thermal management systems represent critical components that significantly impact overall plant efficiency. Waste heat recovery systems capture and utilize the substantial thermal energy produced during electrochemical reactions, either for district heating applications or additional electricity generation through organic Rankine cycles or steam turbines.

Power conditioning systems ensure grid compatibility and power quality while enabling seamless integration with existing electrical infrastructure. Modern installations incorporate advanced inverter technologies that provide grid services including frequency regulation, voltage support, and reactive power compensation.

Hydrogen supply systems vary significantly depending on installation requirements and local infrastructure availability. On-site electrolysis systems enable complete renewable integration but require substantial electrical capacity and water supplies. Delivered hydrogen systems offer operational simplicity but depend on developing hydrogen transportation infrastructure.

Economic Fundamentals and Project Financing

The economics of hydrogen fuel cell power plants continue improving as technology costs decline and operational experience accumulates. Current capital costs range from $3,000 to $8,000 per kilowatt installed, depending on scale, technology selection, and site-specific requirements.

Operational costs benefit from high electrical efficiency and relatively low maintenance requirements compared to conventional thermal generation. Fuel costs currently represent the largest operational expense, though declining hydrogen production costs and improving supply chain efficiency continue reducing this burden.

Revenue opportunities extend beyond electricity sales to include ancillary grid services, thermal energy sales, and carbon credit generation. Many installations qualify for renewable energy certificates and other environmental incentives that improve project economics significantly.

Financing structures increasingly recognize the long-term value proposition of hydrogen fuel cell power plants, with development banks and institutional investors showing growing interest in supporting large-scale deployments. Government policies supporting hydrogen development provide additional revenue certainty through production credits and purchase agreements.

Future Trajectory and Market Evolution

The hydrogen fuel cell power plants market shows accelerating growth momentum driven by technological improvements, cost reductions, and supportive policy environments. Industry projections indicate substantial capacity additions over the next decade as hydrogen supply infrastructure develops and generation costs achieve grid parity.

Technological developments focus on improving durability, reducing costs, and enhancing operational flexibility. Next-generation fuel cell stacks promise extended lifetimes exceeding 100,000 operating hours while maintaining high efficiency throughout their operational life.

Integration with renewable energy systems will drive significant market expansion as hydrogen fuel cell power plants provide the dispatchable generation capability necessary for high-renewable electricity systems. This complementary relationship positions fuel cells as essential components of future energy infrastructure rather than competing technologies.

The convergence of hydrogen production, storage, and utilization within integrated energy hubs represents the ultimate evolution of this technology. These multi-functional facilities will provide electricity generation, industrial hydrogen supply, and energy storage services within unified operational frameworks that maximize economic and environmental benefits.