As the global need for clean energy solutions grows, hydrogen is emerging as an important player in the transition to a more sustainable energy future. Hydrogen can decarbonise a variety of industries, including transportation, industrial processes, and power generation, ultimately rethinking the energy system as a whole. However, realising the full potential of hydrogen depends on the rapid scaling and integration of critical infrastructure, including electrolysers, storage solutions, and refuelling networks.

Electrolysers serve as the backbone of green hydrogen production by splitting water into hydrogen and oxygen using renewable energy. Storage solutions enable the safe storage and transportation of hydrogen, while refuelling infrastructure is required to make hydrogen available to automobiles, businesses, and power plants. Developing a large-scale infrastructure of hydrogen requires innovation, teamwork, and a large investment.

Scaling Electrolyser Capacity for Green Hydrogen Production

The electrolyser is the first step in the hydrogen value chain, implementing water electrolysis technology to decarbonise renewable energy and generate green hydrogen. To meet rising demand for hydrogen, electrolyser production and deployment must be increased while becoming more efficient and cost-effective.

- Advances in Electrolyser Technology

Modern electrolysers are classified into three categories: alkaline, proton exchange membrane (PEM); and solid oxide electrolysers. They all have various benefits depending on the intended use. PEM electrolysers, for example, demonstrate good operational flexibility and can take advantage of variable renewable energy sources (VRES), such as sun and wind.

Recent technological developments in electrolyser technology have concentrated on optimising efficiency and long-term durability. Breakthroughs like advanced catalysts, membrane design optimization, and scalable modular architectures are driving the industrialisation of electrolysers faster. These advances not only increase efficiency in hydrogen production but also the levelized cost of hydrogen (LCOH), making green hydrogen more economically attractive.

A prominent example is the construction of gigawatt-scale factories for electrolysis that utilise automation and digital technologies to facilitate production. Such factories allow for the large-scale production of electrolysers, sharply cutting unit costs and easing global deployment.

Table 1: Comparison of Electrolyser Technologies

| Electrolyser Type | Advantages | Applications |

| Alkaline | Cost-effective, mature technology | Industrial hydrogen production |

| PEM | High efficiency, flexible operation | Renewable energy integration |

| Solid Oxide | High-temperature efficiency | Large-scale industrial applications |

Safe and Scalable Hydrogen Storage Solutions

The safety and efficiency of hydrogen storage are key to establishing a stable hydrogen supply chain. Storage systems need to be able to negotiate the low density and high flammability of hydrogen while also being scalable for application.

- High-Pressure and Cryogenic Storage

Two primary forms of hydrogen storage strategies used today are high-pressure compressed gas storage and cryogenic liquid storage. Storage in high-pressure vessels, often composite materials, is employed where portability is needed, e.g., for fuel cell cars. Recent tank design advancements have focused on increased pressure capacitance and reduced weight, providing both increased performance and safety.

The cryogenic storage of hydrogen necessitates that hydrogen be liquefied by reducing its temperature to cryogenic levels (-253°C). For large-scale applications requiring very large quantities of hydrogen (aviation, marine transport), liquid hydrogen is superior to compressed gas. Storing hydrogen in freezing environments requires advanced insulation technologies to reduce boil-off losses.

- Underground Hydrogen Storage

Subterranean storage of hydrogen in depleted oil reservoirs and salt caverns is a promising option for large-scale storage, in addition to surface storage in tanks or pressure vessels. Natural geological formations can help mitigate both cost and storage potential relative to above-ground storage approaches.

For example, pilot projects have been launched across North America and Europe to examine the potential for salt caverns as storage facilities for hydrogen produced from surplus renewable energy. The projects attempt to create seasonal storage capacity to meet supply and demand, particularly in places where renewable energy output changes.

Chart: Hydrogen Storage Options and Energy Density

| Storage Method | Energy Density (MJ/kg) | Applications |

| High-Pressure Gas | Moderate | Portable applications (fuel cell vehicles) |

| Cryogenic Liquid | High | Large-scale industrial and transportation |

| Underground Storage | Variable | Seasonal storage, renewable energy integration |

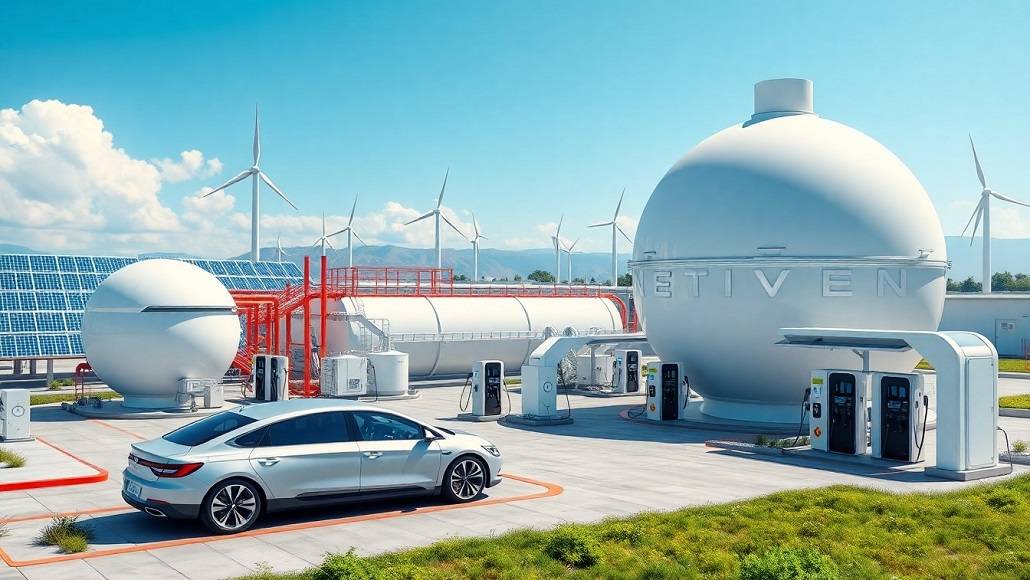

Building a Robust Hydrogen Refuelling Network

The viability of hydrogen as a clean energy carrier is heavily dependent on the availability of an extensive and credible refuelling network. Refuelling stations are critical enablers for the adoption of hydrogen-powered vehicles such as cars, buses, trucks, and trains.

- Scaling Hydrogen Refuelling Stations

To establish a healthy refuelling infrastructure, it is necessary to increase the number of hydrogen refuelling stations (HRS) in urban, suburban, and highway areas. An example HRS would consist of hydrogen storage, compression, cooling, and dispensing functionality.

The construction costs of an HRS are still a significant hurdle for widespread adoption, estimated between $1 million to $2 million per station; however, technology and economies of scale are pushing prices down. For example, modular designs of HRS, which use standardised components, provide for a more efficient installation process and lower capital costs.

- Innovations in Refuelling Technology

Recent innovations in refuelling technology have been focused on efficiency and user convenience. Fast-fill facilities that are able to refuel a passenger car in less than five minutes are rapidly being deployed. The compression and cooling technology developments, allowing for the dispensing of hydrogen at 700 bar pressures for high-pressure fuel cell vehicles, are good examples.

Digital platforms are also improving operational efficiency for HRS. The IoT-supported systems can provide real-time data that gives operators performance data for a station, available hydrogen and maintenance information. The systems used by operators provide efficient management of refuelling operations and other tasks by avoiding downtime while streamlining and maintaining a buoyant experience for consumers.

Table 2: Components of a Hydrogen Refuelling Station

| Component | Function |

| Storage Tanks | Store hydrogen in high-pressure or cryogenic form |

| Compressors | Increase hydrogen pressure for dispensing |

| Cooling Systems | Lower hydrogen temperature for high-pressure dispensing |

| Dispensers | Deliver hydrogen to vehicles safely and efficiently |

The Challenge of Infrastructure Integration

Scaling hydrogen infrastructure, electrolysers, hydrogen storage and refuelling stations are necessary for the hydrogen economy to explode. These infrastructures cannot simply coexist independently of each other, which will be difficult as it requires coordination between stakeholders, including manufacturers, utilities, government/policy-makers, and end-customers.

Policy and Regulatory Support

Public policy and incentives are also important for infrastructure development. Funding for hydrogen production, tax subsidies for recharging stations, and clear laws on storage safety requirements are all crucial to create a favourable environment for investment and innovation.

For instance, the European Union’s Hydrogen Strategy seeks an installed capacity of at least 40 gigawatts of electrolyser capacity and to improve hydrogen refuelling stations within the member states by 2030. The same applies to countries like Japan, South Korea, and the United States, who have all delineated aggressive hydrogen roadmaps to enhance infrastructure whilst also coaxing the market into adoption.

Future Outlook: A Collaborative Hydrogen Ecosystem

The scalability of the hydrogen economy depends on creating a collaborative ecosystem where technological innovation, public-private partnerships, and policy support come together. Electrolyser capacity must be matched with storage capabilities and an extensive refuelling network to ensure a seamless supply chain.

Emerging technologies, like AI-based predictive analytics and blockchain for supply chain visibility, will also unlock greater efficiency and reliability for the hydrogen infrastructure. These technological advances will help the hydrogen sector obtain economies of scale as it meets the global clean energy ambitions while also tackling those challenges of affordability, dependability and accessibility.

Conclusion

Scaling hydrogen infrastructure by refuelling networks, storage systems, and electrolysers is the core to the prosperity of the hydrogen economy. All these infrastructure elements cooperate to facilitate the storage, generation, and transport of hydrogen to make it accessible for multipurpose uses.

While there are still significant barriers to overcome, including high cost and integration issues, it is exciting to see the advancement achieved through policy support and technological advancements. As actors across the hydrogen value chain work together to tackle these challenges, a sustainable hydrogen future is continuing to take shape more clearly.

The future of hydrogen is not technological; rather, it is about developing a resilient and scalable infrastructure capable of supporting the world’s clean energy goals. The concept of a hydrogen economy is possible through collaboration among industrial leaders, governments, and scientists.