Hydrogen & Nuclear Synergy: Building the Nuclear-Hydrogen Hubs of Tomorrow

The convergence of nuclear power and hydrogen production represents one of the most transformative developments in clean energy infrastructure, creating integrated nuclear hydrogen hubs that promise to reshape both electricity generation and industrial fuel supply chains. These sophisticated facilities combine the reliable, carbon-free electricity and high-temperature heat from nuclear reactors with advanced electrolysis technologies to produce massive quantities of clean hydrogen while maintaining continuous power generation capabilities. Nuclear hydrogen hubs offer unparalleled advantages in scale, reliability, and economic efficiency that position them as cornerstone infrastructure for achieving deep decarbonization across multiple sectors.

The Nuclear Advantage in Hydrogen Production

Nuclear power plants provide unique advantages for large-scale hydrogen production that distinguish them from renewable energy sources, primarily through their ability to deliver consistent, high-capacity electricity generation combined with substantial high-temperature heat production. Modern nuclear facilities operate at capacity factors exceeding 90%, providing the steady energy supply essential for maximizing electrolyzer utilization and minimizing hydrogen production costs.

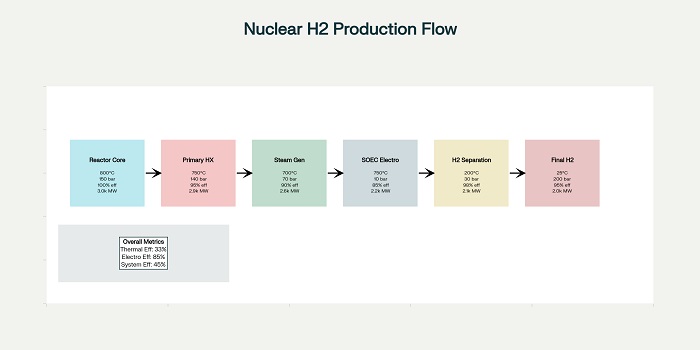

The thermal characteristics of nuclear reactors enable high-temperature steam electrolysis operations that achieve significantly higher efficiency than conventional room-temperature electrolysis. Advanced reactor designs can deliver process heat at temperatures exceeding 700°C, enabling solid oxide electrolysis cells to achieve hydrogen production efficiencies approaching 50% based on higher heating value. This efficiency improvement translates directly into reduced electricity requirements and lower hydrogen production costs.

Nuclear plants’ substantial electrical output capacity enables hydrogen production at industrial scales that can supply regional markets while maintaining grid electricity generation responsibilities. A typical 1,000 MW nuclear plant could dedicate 200-400 MW to hydrogen production during off-peak periods, generating 50-100 tons of hydrogen daily while continuing to serve baseload electricity demands.

The long operational lifetime of nuclear facilities, typically 60-80 years with license extensions, provides the stable investment environment necessary for large-scale hydrogen infrastructure development. This longevity enables nuclear hydrogen hubs to achieve extremely competitive levelized costs of hydrogen production, particularly for plants with fully amortized capital costs that can produce hydrogen at costs below $2 per kilogram.

Nuclear plants’ high energy density and minimal land requirements make them ideal anchor points for industrial hydrogen clusters that co-locate energy-intensive industries requiring both electricity and hydrogen feedstock. This co-location strategy minimizes hydrogen transportation costs while creating synergistic industrial ecosystems that maximize overall efficiency and economic benefits.

High-Temperature Electrolysis Integration

High-temperature steam electrolysis represents the technological cornerstone of nuclear hydrogen hubs, leveraging the elevated heat output from nuclear reactors to achieve superior hydrogen production efficiency compared to conventional electrolysis methods. This advanced process operates at temperatures between 700-850°C using solid oxide electrolysis cells that combine electrical power with thermal energy to split water vapor into hydrogen and oxygen.

The thermodynamic advantages of high-temperature electrolysis become apparent when comparing energy requirements across different temperature ranges. While conventional electrolysis requires approximately 50-55 kWh per kilogram of hydrogen, high-temperature systems can reduce this requirement to 35-40 kWh per kilogram by utilizing thermal energy that would otherwise be wasted in conventional power generation cycles.

Solid oxide electrolysis cells operate in reverse to solid oxide fuel cells, employing ceramic electrolytes that become ionically conductive at elevated temperatures. These systems can achieve electrical efficiencies exceeding 85% while simultaneously utilizing waste heat that improves overall system efficiency to levels approaching 50% thermal-to-hydrogen conversion efficiency.

The integration of high-temperature electrolysis with nuclear reactors requires sophisticated heat management systems that extract thermal energy at appropriate temperature levels while maintaining reactor safety and operational flexibility. Advanced heat exchanger designs enable steam generation at the precise conditions required for optimal electrolysis operation while maintaining isolation between nuclear and hydrogen production systems.

Current development programs focus on improving solid oxide cell durability and reducing degradation rates that currently limit system lifetime. Research initiatives target cell lifetime improvements to exceed 40,000 operating hours while maintaining high efficiency, making commercial deployment economically viable for nuclear hydrogen hub applications.

Idaho National Laboratory has demonstrated high-temperature electrolysis systems coupled with nuclear reactors that can produce hydrogen at rates exceeding 2.5 kilograms per second from a 600 MW thermal reactor, equivalent to large-scale steam methane reforming facilities but without carbon emissions. These demonstrations validate the technical feasibility of integrating nuclear heat with advanced electrolysis technologies.

Advanced Reactor Technologies for Hydrogen Applications

Next-generation nuclear reactor designs specifically optimize heat output characteristics for hydrogen production applications, offering superior performance compared to conventional light water reactors through higher operating temperatures and improved thermal efficiency. High-temperature gas-cooled reactors represent the most mature advanced reactor technology for hydrogen applications, capable of delivering process heat at temperatures exceeding 850°C.

Very High-Temperature Reactors under development can achieve coolant outlet temperatures approaching 1000°C, enabling thermochemical hydrogen production processes that promise even higher efficiencies than high-temperature electrolysis. These systems could achieve thermal-to-hydrogen efficiencies exceeding 60% through direct thermochemical water splitting without requiring electricity for the electrolysis process.

Small Modular Reactors offer unique advantages for distributed nuclear hydrogen hub deployment, providing scalable solutions that can be deployed closer to industrial demand centers while reducing capital investment requirements. SMR designs can be specifically optimized for cogeneration applications that simultaneously produce electricity and hydrogen, maximizing overall energy utilization efficiency.

Molten Salt Reactors promise exceptional flexibility for hydrogen production applications through their ability to rapidly adjust power output and heat delivery to optimize electrolysis operations. These systems can accommodate the variable electrical demands of large-scale electrolysis while maintaining stable reactor operation, enabling dynamic optimization of hydrogen production based on electricity prices and grid conditions.

Fast reactor technologies being developed in Russia, China, and other countries offer high-temperature operation capabilities that make them well-suited for hydrogen production through both thermochemical cycles and high-temperature steam electrolysis. These reactors can operate at temperatures exceeding 500°C while providing the neutron-rich environment necessary for advanced fuel cycles.

The Korean HTGR program has demonstrated reactor outlet temperatures reaching 950°C, sufficient for supporting large-scale hydrogen production through multiple pathways. Recent tests indicate that commercial deployment of these systems could enable hydrogen production costs competitive with steam methane reforming while eliminating carbon emissions entirely.

Nuclear-Hydrogen Hub Development Models

Nuclear hydrogen hubs can be configured in multiple operational models that optimize different combinations of electricity generation, hydrogen production, and industrial supply to maximize economic value while serving diverse market requirements. Baseload electricity generation with off-peak hydrogen production represents the most conservative approach, utilizing excess nuclear capacity during low electricity demand periods to produce hydrogen for storage and later use.

Dedicated hydrogen production facilities co-located with nuclear plants can maximize hydrogen output by dedicating substantial reactor capacity specifically to electrolysis operations while maintaining grid electricity supply during peak demand periods. This model enables hydrogen production at scales that can supply regional industrial clusters while providing grid flexibility services.

Industrial cogeneration hubs integrate nuclear electricity and hydrogen production with energy-intensive industrial processes that require both forms of energy. Steel production, chemical manufacturing, and synthetic fuel production facilities can locate adjacent to nuclear hydrogen hubs to minimize energy transportation costs while creating integrated industrial ecosystems that maximize overall efficiency.

Seasonal optimization models adjust the split between electricity and hydrogen production based on seasonal demand patterns and renewable energy availability. During summer months with high renewable output, nuclear plants can increase hydrogen production to provide seasonal storage, while winter operations focus on electricity generation to meet heating demands.

Export-oriented hydrogen hubs locate near nuclear facilities with access to transportation infrastructure that enables large-scale hydrogen export to distant markets. These facilities can produce hydrogen at scales that supply international markets while providing domestic electricity generation and industrial supply capabilities.

The integration of carbon capture and utilization technologies with nuclear hydrogen hubs enables synthetic fuel production that converts carbon dioxide and hydrogen into methanol, synthetic diesel, or other carbon-neutral fuels. These integrated facilities can provide complete fuel cycle solutions that replace fossil fuel imports while generating additional revenue streams.

Economic Analysis and Investment Considerations

The economics of nuclear hydrogen hubs benefit from unique advantages that distinguish them from other hydrogen production methods, particularly the ability to leverage fully amortized nuclear assets that dramatically reduce the cost of energy inputs for hydrogen production. Existing nuclear plants with extended operating licenses can produce hydrogen at costs below $2 per kilogram when utilizing off-peak capacity that would otherwise generate low-value electricity.

Capital investment requirements for nuclear hydrogen hub development vary significantly depending on the integration approach and scale of hydrogen production facilities. Retrofitting existing nuclear plants with high-temperature electrolysis systems requires investments of $1,500-3,000 per kilowatt of electrolysis capacity, while new nuclear plants designed for cogeneration can achieve lower unit costs through optimized integration.

The revenue diversification enabled by nuclear hydrogen hubs improves overall project economics compared to electricity-only nuclear plants by providing multiple income streams that reduce market risk. Hydrogen sales, electricity generation, industrial steam supply, and grid services create diverse revenue portfolios that improve financial stability and investor confidence.

Operational cost advantages stem from nuclear plants’ high capacity factors that maximize electrolyzer utilization compared to renewable-powered systems that experience capacity factors below 40% in most locations. Nuclear-powered electrolysis can achieve capacity factors exceeding 80%, dramatically improving the economics of hydrogen production by spreading capital costs over higher production volumes.

The long-term price stability of nuclear-produced hydrogen provides significant advantages for industrial users requiring predictable fuel costs for long-term planning and contracting. Unlike hydrogen from renewable sources that may experience price volatility due to weather variations, nuclear hydrogen production can provide stable pricing over decades.

Government support programs increasingly recognize nuclear hydrogen production as essential for achieving climate targets, with several jurisdictions providing specific incentives for nuclear-hydrogen integration projects. The United States has allocated $7 billion for regional hydrogen hubs, with nuclear power specifically included in several selected projects that recognize its unique advantages for large-scale clean hydrogen production.

Safety, Regulatory, and Operational Framework

The integration of hydrogen production with nuclear facilities requires comprehensive safety frameworks that address the unique challenges of combining nuclear operations with hydrogen handling and storage systems. Regulatory approaches focus on maintaining complete isolation between nuclear safety systems and hydrogen production operations while ensuring adequate safety margins for hydrogen storage and handling.

Nuclear-hydrogen facilities employ defense-in-depth safety principles that apply multiple independent barriers to prevent any potential interaction between nuclear and hydrogen systems. Hydrogen production areas maintain physical separation from nuclear operations while employing dedicated safety systems that can rapidly isolate hydrogen production in response to any operational anomaly.

Hydrogen detection and mitigation systems within nuclear facilities utilize advanced sensor arrays and automated response systems that can detect and address hydrogen leaks before they pose safety risks. These systems integrate with existing nuclear plant safety instrumentation to provide comprehensive monitoring and protection capabilities.

Regulatory frameworks continue evolving to accommodate nuclear-hydrogen integration while maintaining existing nuclear safety standards and establishing appropriate oversight for hydrogen production operations. Multiple regulatory agencies coordinate oversight responsibilities to ensure comprehensive safety review while avoiding duplicative requirements that could impede development.

Operational procedures for nuclear hydrogen hubs emphasize maintaining nuclear plant operational priorities while optimizing hydrogen production within safety constraints. Emergency procedures ensure that hydrogen production can be rapidly isolated and shut down without affecting nuclear plant safety or electricity generation capabilities.

International safety standards and best practices are being developed through collaboration between nuclear and hydrogen industry organizations to establish common approaches for nuclear-hydrogen integration projects. These standards will facilitate technology transfer and reduce development costs while maintaining high safety standards.

Global Development and Market Prospects

Nuclear hydrogen hub development shows accelerating momentum globally, with major nuclear power countries developing comprehensive programs that integrate hydrogen production with existing and planned nuclear facilities. The United States leads this development through its National Clean Hydrogen Strategy and substantial federal funding for demonstration projects that include nuclear-powered hydrogen production.

China’s aggressive nuclear expansion program increasingly incorporates hydrogen production capabilities, with several new nuclear plants specifically designed for cogeneration applications that can supply both electricity and hydrogen to industrial users. Chinese nuclear developers are integrating high-temperature electrolysis capabilities into advanced reactor designs to maximize hydrogen production efficiency.

European nuclear operators are developing retrofit programs that add hydrogen production capabilities to existing nuclear plants while maintaining electricity generation responsibilities. These programs focus on high-temperature electrolysis integration that can utilize waste heat from existing reactor designs while maximizing overall energy efficiency.

Russia’s advanced fast reactor program includes hydrogen production capabilities that leverage high-temperature operation to enable both thermochemical and electrolysis-based hydrogen production. These systems promise exceptional efficiency while providing the large-scale hydrogen supply necessary for industrial decarbonization.

Canada’s nuclear-hydrogen integration program focuses on CANDU reactor modifications that enable hydrogen production while maintaining electricity generation capabilities. These efforts target both domestic industrial supply and export opportunities that leverage Canada’s abundant nuclear capacity and proximity to major hydrogen markets.

International collaboration on nuclear hydrogen technologies accelerates development through shared research programs, technology demonstrations, and regulatory harmonization efforts. The International Atomic Energy Agency provides coordination and technical support for member countries developing nuclear-hydrogen capabilities.

The market potential for nuclear hydrogen hubs extends far beyond current hydrogen demand projections, with studies indicating that nuclear facilities could supply 15% of projected 2030 hydrogen demand using just ten existing reactors. This massive potential positions nuclear hydrogen hubs as essential infrastructure for achieving global decarbonization targets while providing economic benefits that support continued nuclear power development.